Bearing hardness is typically expressed in Rockwell hardness (HRC), with a common range of 60-65.

The key role of hardness in bearings

1. Contact fatigue strength

Hardness directly affects the bearing surface's resistance to wear.

2. Wear resistance

High hardness reduces the wear rate of components such as rings and rolling elements, extending their service life.

3. Elastic limit

Appropriate hardness balances material toughness and rigidity, preventing plastic deformation and resulting loss of precision.

The classification of bearing metallographic structure is mainly based on metallographic rating standards, and different levels correspond to different organizational characteristics and mechanical properties, which directly affect the durability, wear resistance, and dimensional stability of bearings.

The microstructure classification of martensitic quenching and tempering process for conventional high carbon chromium bearing steel is usually divided into five levels:

Grade 1: uniform structure, mainly lath martensite, less residual austenite, uniform carbide distribution, excellent wear resistance.

Level 2: Flake martensite begins to appear in the organization, with slightly uneven distribution of carbides and good dimensional stability.

Level 3: The proportion of lamellar martensite increases, and the distribution of carbides is uneven, which may lead to local carbide aggregation.

Level 4: Significant increase in flaky martensite, uneven distribution and large size of carbides, which can easily cause local wear.

Level 5: Obvious cracks or inclusions appear in the organization, and the size of carbides is too large, leading to an increase in material brittleness.

one

The impact on bearing performance

Wear resistance: The first level structure has the highest wear resistance due to the uniform distribution of carbides and dense martensitic structure; Due to the large size of carbides and the presence of cracks, the wear resistance of level 5 organization significantly decreases.

Dimensional stability: Level 1 organization has the best dimensional stability due to the uniform distribution of carbides and the absence of cracks; Organizations above level 3 are prone to size fluctuations due to uneven distribution or defects of carbides.

Fatigue strength: 1-2 grade tissues have better toughness and fatigue resistance; 4-5 level organizations are prone to fatigue spalling due to increased brittleness

The axial detection of bearings (which may refer to the detection of working clearance) plays the following key roles in the operation of equipment:

Improve the stability of equipment operation

Excessive axial clearance can cause abnormal vibration and noise during bearing operation, affecting equipment accuracy; If the clearance is too small, it can cause overheating, accelerated wear due to increased friction, and even lead to bearing jamming. Regular testing can ensure that the clearance is within a reasonable range and maintain the smooth operation of the equipment.

one

Extended service life

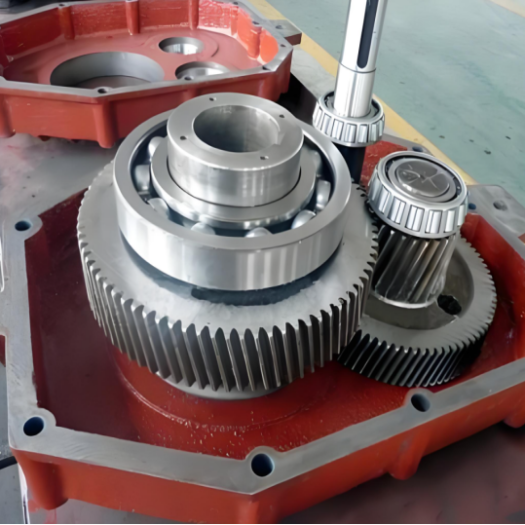

Abnormal axial clearance can accelerate metal fatigue inside the bearing, leading to early damage. After testing, adjusting the clearance can optimize the load distribution, reduce component wear caused by uneven force, and indirectly extend the service life of bearings and related components (such as gears and transmission shafts).

one

Reduce energy consumption

Improper clearance can increase mechanical operating resistance, leading to an increase in power system load and energy consumption. Reasonable detection and adjustment can optimize power distribution and reduce energy waste, especially in high-speed operation scenarios where the effect is significant.

one

Enhance security

Abnormal axial clearance may cause equipment vibration, overload and other problems, indirectly increasing the risk of failure. Regular inspections can detect hidden dangers in advance, avoid chain failures caused by bearing failure (such as mechanical overturning, loss of control, etc.), and ensure production safety.

The main benefits of bearing radial inspection include:

Ensure stable operation of equipment

By detecting the radial state of bearings, dimensional deviations or assembly problems can be detected in a timely manner, avoiding equipment vibration, accuracy degradation, and even mechanical failures caused by excessive radial runout.

one

Improve production efficiency

Regular testing can prevent downtime and maintenance caused by abnormal bearings, reduce production interruption time due to faults, and ensure continuous operation of the production line.

one

Extend equipment lifespan

By monitoring the radial force on the bearings, the lubrication scheme and assembly accuracy can be optimized, reducing component damage caused by wear or insufficient lubrication, and extending the overall service life of the equipment

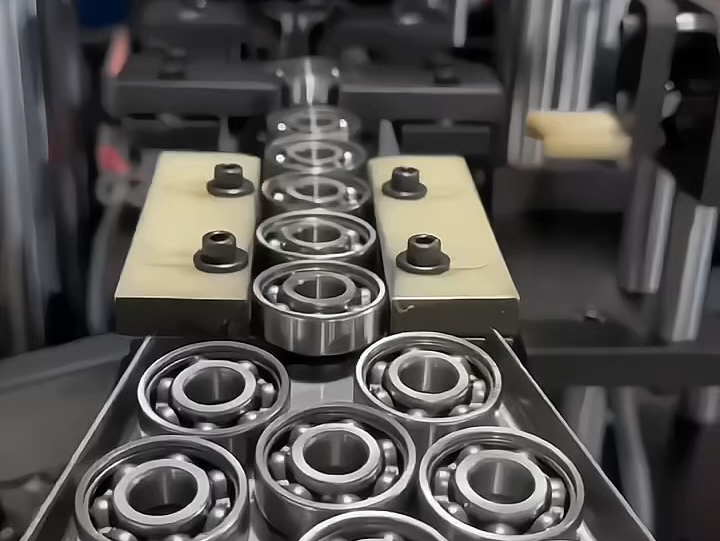

1. Our bearings are installed using automatic assembly machines, which reduces manual installation costs by 20%. 2. We use automatic cartoning machines for boxing, significantly reducing labor costs by 65%. 3. We grind bearing rings inline, allowing one person to operate multiple machine tools. All machining is done using CNC machines, ensuring more stable control over product precision. Our testing is also automated, improving quality while reducing costs.

High-quality bearing steel Gcr15 is used. Large bearings are made of silicon-manganese steel. For different use environments, low-speed bearings are made of high-carbon steel.

The bearing forging process is the core process of converting metal materials into bearing ring blanks through pressure processing. It directly affects the geometric accuracy, mechanical properties and service life of the bearing, making the density of the bearing ring more compact and eliminating the occurrence of undesirable conditions such as pores and interlayers.

The bearing rings are processed by a high-precision CNC machining center and use anti-ovality tooling. After processing, the ovality of the bearing is controlled within 0.01mm, which reduces the stress on the bearing during the processing, lays a better foundation for the bearing in the grinding process, and is also a key step in improving the bearing accuracy.

The main advantages of heat-treating bearings using bainite include:

1. High dimensional stability

The bainite transformation occurs almost simultaneously at the surface and core, resulting in uniform volumetric changes and effectively controlled expansion (average expansion of approximately 3‰ for walls up to 20mm thick), minimizing processing distortion.

2. Excellent mechanical properties

Improved impact toughness: Bainite is more resilient than martensite, resulting in an approximately 30% increase in fracture toughness (KIC) and a slower crack growth rate.

3. Surface Pressure: After quenching, the surface pressure reaches -400 to -500 MPa, reducing the risk of cracking. 4. Flexural Strength and Wear Resistance: Stable surface hardness (59 to 61 HRC) effectively reduces cracking.

4. Wide Applicability: It can handle thicker parts (effective wall thickness up to 28 mm) and is suitable for high-impact, low-lubrication conditions (such as railways, rolling mills, and mining machinery).

5. Extended Life: The bainite structure reduces assembly cracking, outer ring chipping, and inner ring fragmentation, thereby improving overall bearing wear.

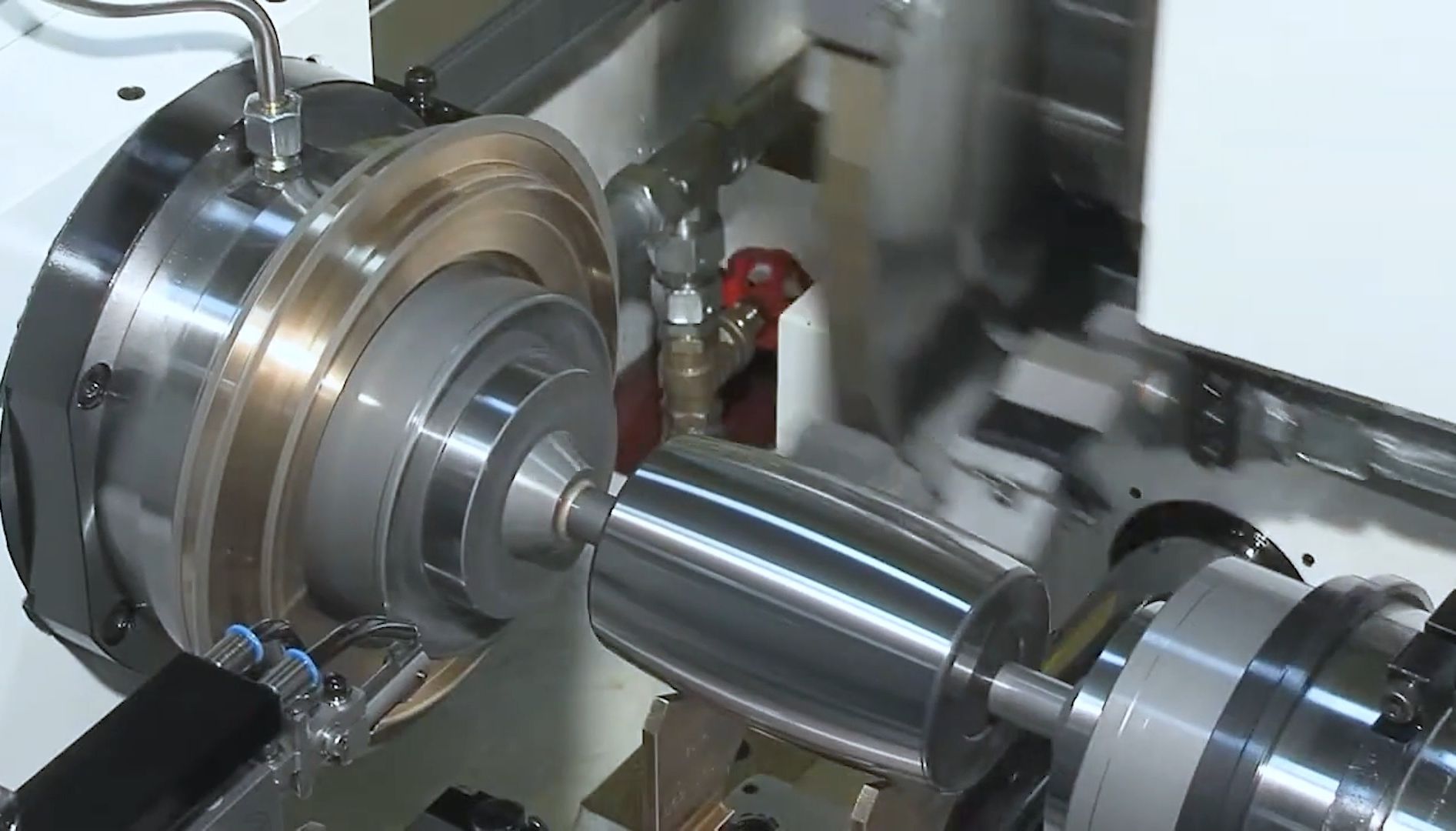

Bearing grinding is performed using high-precision CNC machine tools. The advantages of CNC grinding lie primarily in high-precision machining, efficient production, automated operation, and adaptability to complex part processing.

CNC grinders offer high positioning accuracy and repeatability, ensuring consistent dimensional consistency across a batch of parts. Machining accuracy typically reaches ±0.01mm. Through appropriate programming and process design, high-precision machining can be achieved with robust process stability.

The machining process is automated by program control, requiring the operator to perform only initial operations such as tool setting and workpiece loading and unloading. This automated process reduces manual intervention and significantly improves production efficiency, with pure cutting time accounting for up to 70%-80%.

After the successful pilot production of a CNC grinding machine suitable for complex part machining, process files and programs can be reused in subsequent production runs, significantly shortening production cycles and reducing costs. Compared to specialized grinding machines, this significantly saves the expense of specialized process equipment.

It can handle complex parts that conventional grinding machines cannot process, such as special-shaped shafts, mold components, and those requiring multi-axis machining. For example, CNC cylindrical grinding machines can grind toroidal surfaces, concave and convex surfaces, and combined surfaces, expanding the machining range.

For high-precision bearings, we use reciprocating double-end surface machining to control the balance error of the bearings to between 0.0005 and 0.001. After grinding, the rings are free of warping and deformation. The second step is precision grinding using a grinder to reduce the roughness of the bearing surface, laying a good foundation for subsequent inner diameter grinding, outer diameter grinding, and groove grinding. The bearing accuracy can reach high precision requirements such as P5, P4, and P2.

Bearings are automatically packaged, large automatic cleaning agents are used for bearing cleaning, plastic bags inside bearings are automatically packed by pillow-type packaging machines, and bearing boxes are packed by large automatic cartoning machines, which reduces manual errors, improves production efficiency, saves costs better, and is more competitive in the market.

Process quotation within 1 hour after receiving inquiry

We will respond to your inquiry within 10 minutes after receiving your inquiry

Always follow up product dynamics and report to you at any time

Follow up and control the quality at all times, confirm with you one by one through product pictures and videos

Strictly control the time concept and never delay delivery

Always pay attention to logistics dynamics and report any updates to you in a timely manner

Deal with any product issues in the shortest possible time

Professional technical team to assist you in sales and customized product development

You can go to our Weibo, where we will always update our dynamics, production, packaging, testing, exhibitions and all other details of our daily life and work.

Dawei (Shandong) Bearing Manufacturing Co., Ltd. is a large-scale bearing manufacturer in China, specializing in the production and wholesale of bearings. We specialize in the following types of bearings: