Our factory, formerly known as Linqing Special Axis Bearing Factory, was established in 1996 and has 30 years of experience in bearing manufacturing. We specialize in the production of spherical roller bearings, deep groove ball bearings, outer spherical bearings, tapered roller bearings, and customized development of non-standard bearings. The factory covers an area of 4,600 square meters and has more than 50 sets of advanced CNC processing equipment and more than 20 sets of high-precision testing equipment. We mainly engage in bearing wholesale business, supplying thousands of stores at home and abroad with high-quality products at low prices.

1. Excellent Sealing Performance

A special sealing design effectively isolates gas and liquid leaks, making it suitable for applications requiring a sealed environment, such as sewage treatment tanks and chemical tanks, to prevent the escape of harmful gases and the infiltration of pollutants.

2. Strong Corrosion Resistance

The fiberglass reinforced plastic material is resistant to acids, alkalis, and salt spray, making it suitable for corrosive environments such as chemical and sewage treatment, with a service life of over 10 years.

3. High Load-bearing Capacity

The load-bearing rating meets Class A standards, capable of withstanding the pressure of heavy vehicles or equipment, making it suitable for applications requiring high loads, such as municipal sewage lift pumping stations.

4. Anti-aging and Durable

The surface is treated with a special process to effectively block UV rays and chemical corrosion. It is resistant to fading or cracking with long-term use, and has low maintenance costs.

5. Easy Installation

Customizable sizes and shapes (such as arched and round) are supported, allowing for quick adaptation to various sewage tank structures, making installation simple and efficient.

1. Excellent Sealing Performance

A special sealing design effectively isolates gas and liquid leaks, making it suitable for applications requiring a sealed environment, such as sewage treatment tanks and chemical tanks, to prevent the escape of harmful gases and the infiltration of pollutants.

2. Strong Corrosion Resistance

The fiberglass reinforced plastic material is resistant to acids, alkalis, and salt spray, making it suitable for corrosive environments such as chemical and sewage treatment, with a service life of over 10 years.

3. High Load-bearing Capacity

The load-bearing rating meets Class A standards, capable of withstanding the pressure of heavy vehicles or equipment, making it suitable for applications requiring high loads, such as municipal sewage lift pumping stations.

4. Anti-aging and Durable

The surface is treated with a special process to effectively block UV rays and chemical corrosion. It is resistant to fading or cracking with long-term use, and has low maintenance costs.

5. Easy Installation

Customizable sizes and shapes (such as arched and round) are supported, allowing for quick adaptation to various sewage tank structures, making installation simple and efficient.

1. Dust and Waterproof

The rubber sealing cover effectively blocks dust and moisture from entering the bearing, preventing foreign matter from intruding and causing lubricant loss and component wear, while also preventing moisture-induced rust.

2. Maintenance-Free Design

Bearings using rubber seals are typically sealed for life, eliminating the need for regular grease relubrication and simplifying maintenance.

3. Applicability

Rubber seals operate stably in temperatures ranging from -35°C to 165°C, are corrosion-resistant, and offer high ductility, making them particularly suitable for operating conditions requiring frequent starts and stops or varying loads.

4. Noise and Friction Reduction

Compared to metal dust covers, rubber sealing covers offer lower friction, quieter operation, and are suitable for high-speed operation.

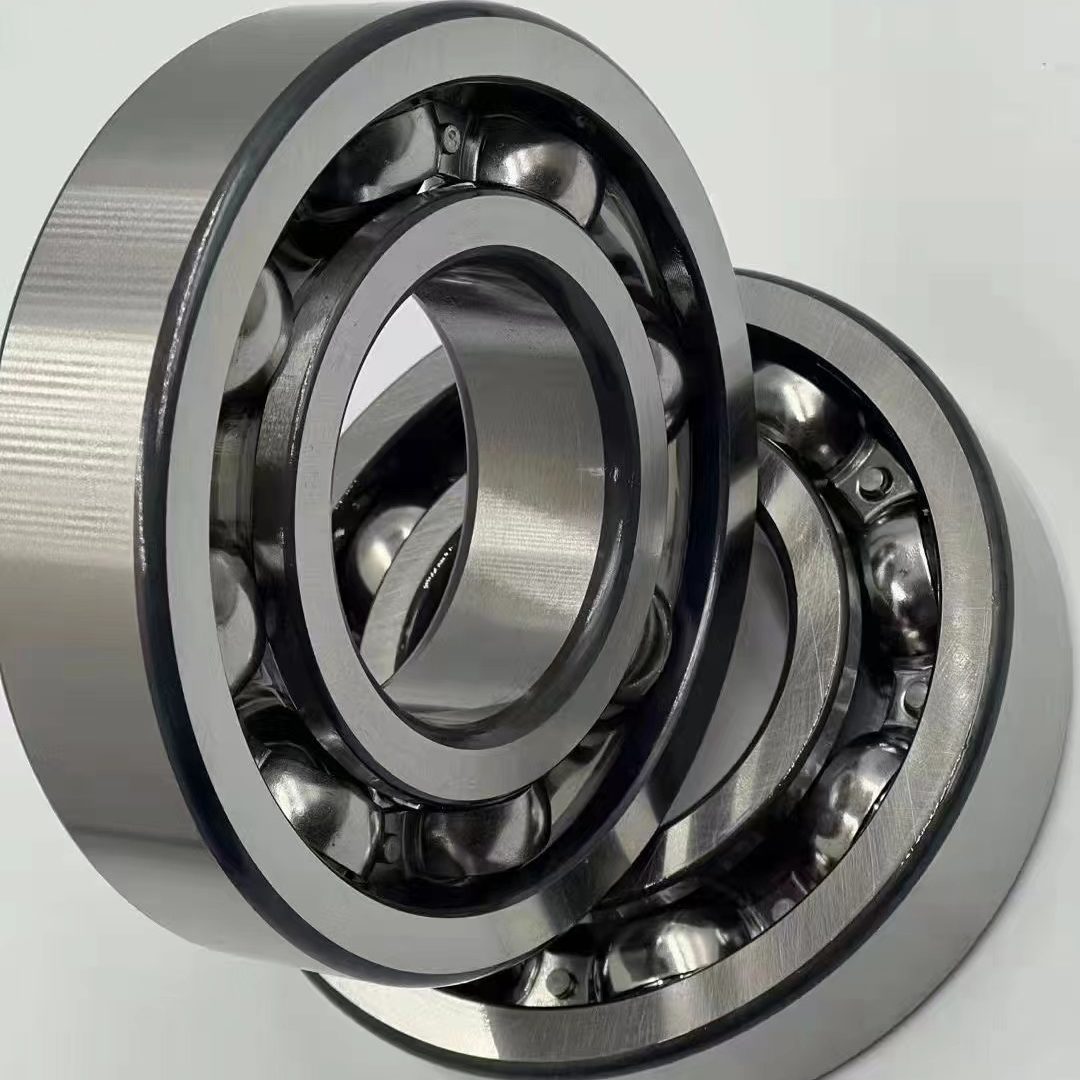

1. Reduced Friction

Because they lack a seal, uncapped bearings experience relatively low friction, making them suitable for applications requiring high speeds or high loads, such as in automobiles and ships.

2. Improved Lubrication Efficiency

In environments with good lubrication conditions and a clean environment, uncapped bearings provide more complete access to grease or oil, reducing lubricant loss due to the seal structure and maintaining more stable lubrication.

3. Simplified Structural Design

Some coverless bearings (such as motor bearings) can eliminate the need for inner and outer covers, simplifying the assembly process and reducing manufacturing costs. However, it should be noted that this design places high demands on the lubrication system and requires the use of circulating lubricant.

4. Wider Applicability

In environments with low dust levels or good lubrication conditions, coverless bearings offer greater versatility and are particularly suitable for industrial applications requiring frequent disassembly or maintenance.

We can carry out customized development of various types of bearings according to customer samples or drawings, customized sizes, customized materials, as well as special stainless steel bearings, rubber-coated bearings, door and window pulley bearings, etc.

Find us through the contact information on the website, such as WeChat, WhatsApp, email, etc. We will reply you in time after receiving your message and ask you about the details of the product.

We will give you the best wholesale price based on the quantity, quality grade required, as well as the shipping method and packaging method.

After we ship the goods, we will provide you with the following documents and assist in receiving the goods.

Dawei (Shandong) Bearing Manufacturing Co., Ltd. is a large-scale bearing manufacturer in China, specializing in the production and wholesale of bearings. We specialize in the following types of bearings: